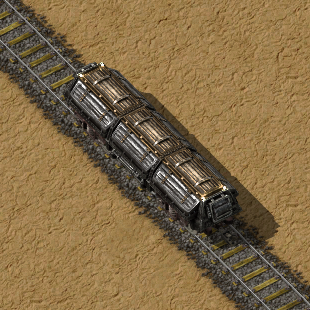

Cargo wagon

| Cargo wagon |

Object description

The Cargo wagon is used in conjunction with locomotives to form trains for the railway.

A wagon is used to transport items and can be filled and emptied like a chest, but with many more inserters at the same time. Up to 12 inserters per wagon are possible (from both sides). The inserter item stack size is important to fill the wagon fast!

In manual-mode cargo wagons can only be filled or emptied when they are not moving and horizontally or vertically orientated. In automated-mode it is the same, but additionally they can only filled/empty, when stopped on a train-stop (not at a signal). A spot where inserters are prepositioned to transfer cargo for wagons is called a train station.

Stack limitation

Wagons have a stack limitation option the same way chests do, which is useful if you need to limit the number of transported items for some reason.

Stack filter

Each stack in the cargo wagon can be filtered. This works in the same way as the quick bar (toolbelt); the default key to define or remove the filter is the middle mouse button.

This can be used to transport different items in one wagon. For example, you could transport both empty and full oil barrels in one wagon; at the train stations, the barrels would be handled using smart inserters for each kind of barrel. This is discussed in the forum thread Tired of babysitting expansions? Auto-supply w/ trains!.

Compressing items

A cargo wagon can be filled with 2000 items of ores (copper, iron, coal...) or 4000 items of processed plates (copper plates, iron plates, steel). This makes preprocessing your ores into plates (near the mines) a useful strategy, before you transport it to your factory.

Pre-production reduces needed space

As you see in Transport belts/Physics, the throughput depends on density and density on space (or on belt length). So when you reduce the required space, you increase throughput. You cannot make items smaller, but you can compress them!

Assuming that you have a combination of coal and iron ore in close quarters, but are far away from your base factory, the pre-production of steel makes sense. This is because 1 steel needs 5 iron ore, so the iron ore is compressed by a factor of 5! This means that the output of 50+ iron ore mines can be easily transported with one lane of a basic belt, which is much cheaper and easier to build than a train. And the overflow can be transported with the other side of the belt. Nothing can be faster and you only need miners, furnaces, belts and inserters. This can also be done with other items (see below). It also makes sense to power external mines with only solar power, to reduce the extreme pollution.

The downside to this approach is that you don't have as much control over production rates as when you produce the stuff in your central factory. This is due to the long transport distances involved, so the reaction to under or over production is slow. Use such external factory parts as "basic supply" and produce the rest in your main factory on demand.

Good candidates:

- steel plates (5 iron plates => 1 steel plate, 5/1)

- electronic circuit (1 iron plate + 1.5 copper plates => 1 electronic circuit, 5/2; more complex, because you also need copper; so doesn't always makes sense, if the resources aren't within reach)

- Transport belts (3 iron plates => 2 belts, 3/2) if you limit the output, because most you need yourself)

- any items that need lots of resources, but which you also need in large quantity.

For example: inserters compress well (11/2), but aren't needed in large quantity. The pre-production of iron gear wheels is also questionable (2/1), because it only has a compression factor of two and they are normally needed immediately, but not in large quantity. On-demand production seems to be better for that. On the other hand, the pre-production of Firearm magazines makes sense, because there is no dependency.

Bad candidates:

- copper cables (1/2 !!)

- any item that doesn't compress or even inflates when produced

Note that with the productivity modules this technique may become more or less effective.

Compression for trains

When using mining outposts (> 500 tiles distant) connected by train you should smelt the ore locally at your outposts. This is because you can store only 50 ores in a stack, compared to 100 furnaced materials! That doubles the capacity of wagons and makes routing easier.

There are quite significant differences for the stack sizes:

- Ore, stone and coal have a stack size of 50.

- Iron/copper plates and so on have significantly bigger stack sizes: 100

- Processed materials such as electric circuits: 200

This means that you can transport much more with fewer wagons!

For example: instead of two wagons, one with copper and one with iron ore you can transport the same amount with one wagon, half copper/iron plates. Or even less if you produce electric circuits or iron wheels. You can regulate the production of the materials by unloading only the required stuff using a logistic network.

Program the stacks of the wagons (since v0.10) to transport multiple materials in one wagon, without overfilling.

Danger: furnaces and assemblies produce Pollution.

Use as a big chest

It is possible to use the cargo wagon as a "big chest": Place rails, put an unmoving wagon on it and inserters around. The advantages of this construction are:

- Cargo can be transferred with many more inserters than with a chest, bypassing the limitations of the inserter stack size bonus.

- Items are transported instantly over the length of the wagon. Correctly configured, this is faster than a transport belt.

For examples of this, see these forum threads:

- Solar panel factory

- Cargo wagon sourced RGB circuits production facility

- Mass production with ZERO belts and robots