Tutorial:Quick start guide

Getting started

If you're still lost after playing through the tutorial levels, this guide is here to help.

Starting your game

To begin from the Main Menu, you need to select "Play", then "New Game". This will lead you to a menu allowing the customization of your world. If this is your first time, you won't need to tinker with these. If you haven't yet played the tutorial and campaign levels yet, you should play these first however. From the main menu, select "Play", then "Start Campaign", then "First Steps". The "First Steps" campaign is a basic tutorial, the "New Hope" further teaches the basics of the game.

World generator

You can change these options to make the map generate in different ways. Changes to world generation can greatly affect the difficulty of the game.

The first tab in the world generation screen allows the player to choose a preset for the world generation. A preset is just a quick way to change the settings in the other two tabs. For new players, the Default preset or the Rich Resources preset are suggested.

If peaceful mode is enabled, enemies will not attack the player unless the player attacks first.

The Resource Settings tab allows changing how frequently and strongly resources and enemies spawn.

Resources and enemy bases are controlled by 3 values: frequency, size, and richness.

- Frequency determines how often you'll see ore veins or enemy bases within the game world

- Size determines how large these veins or bases are

- Richness determines how many resources ore tiles will produce before running dry, and the density of enemy bases

If you would like an easier time to begin with, consider increasing the frequency, size, and richness of the resources while decreasing the same for enemy bases. Note that it may be recommended to increase the size and frequency of crude oil for beginner-level players, as oil can be very difficult to find depending on the world generation seed compared to that of other resources, combined with the fact that oil is a necessity for making progress as well the fact that pumping oil will gradually decrease it's yield, requiring the need travel further to find even more oil. Also note that the game can be completed with enemies disabled completely (set size to none), however dealing with enemies is usually a major part of the game.

More information about world generation can be found in the World generator article.

Key bindings

Please refer to Keyboard bindings to learn more about key bindings and how to configure them.

The very first moments

Resources

Make sure that you have the four solid resources close to your spawn location; Coal, Copper ore, Iron ore, and Stone. These should be found within a reasonable proximity to each other; the farther apart they are the harder it will be to route them for combined use.

It's also advisable to have a source of Water in your starting area, as it is required for Steam Engines.

If your spawn area doesn't have one of these resources, or they are too scarce or too far apart, simply hit the Escape key and choose "Restart." This will re-generate the game world and you will spawn in a new starting location. This may need to be done several times until a passable world is created.

Later we will also need Crude oil. However, being a liquid, it is much easier to transport over distance than the four solid resources. It's okay if your starting area doesn't have immediate access to oil, as you won't need it until later in the game when long distance liquid transfer is possible. The same goes for for Uranium ore. It is used for end-game power and weapons and it can only be mined after oil has been acquired.

Almost everything in Factorio is made from these seven basic resources, and you will need all of them except for uranium if you intend to finish the game.

Placing mines and furnaces

You begin your journey with a Stone furnace and a Burner mining drill. This means you only have to harvest a limited number of resources by hand. First of all, you should place your drill on the edge of an iron deposit, facing towards the furnace.

Open your inventory ("E" key by default), and click the "Burner mining drill". You should see that your cursor has been replaced by the drill icon. Press the same inventory button again ("E" by default) to close your inventory.

Now you need to place the drill. Move your mouse around the world, and you will see that the drill turns green when it is over your iron deposit. Left click to place it at the edge of the iron deposit.

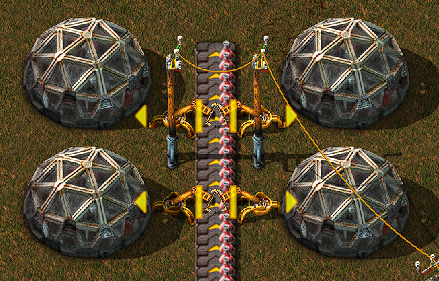

You can change the direction of the drill by either pressing the rotate key ("R" by default) before you place it, or after placing it by hovering over it with the mouse and pressing the rotate key ("R" by default). The little yellow arrow shows where the mined iron ore will come out. You want the Furnace to be in front of that arrow, so that the drill automatically inserts the ore into the furnace. It should look something like this:

Remember you can press "ALT" to activate the detailed view. This makes it easier to see what's happening.

Feeding with fuel

Now that you've placed the drill and furnace, they need Fuel.

You can power them with either Wood or Coal. To collect them, you'll need to cut trees or mine coal; this can be accomplished by holding right click over trees or coal deposits, respectively.

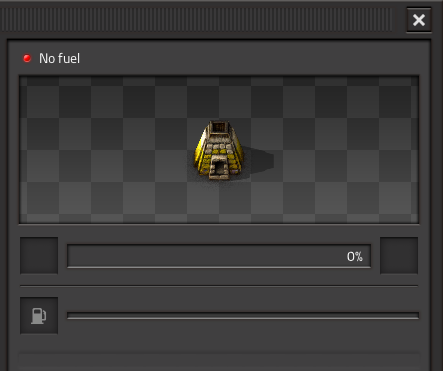

Once you have some fuel in your inventory, left click on the furnace or drill to open the interface.

To place your fuel into the machine, simply left click it to pick it up and left click again to put it into the fuel slot.

If you want to split a stack in half, right click the stack in your inventory and then place it in the fuel slot. Now both of your machines should be running and automatically making you some iron plates!

You can also CTRL-Right Click to directly insert half of the stack

You can use an identical setup for copper ore to get copper plates.

Production upgrade!

What's better than iron plates? More iron plates!

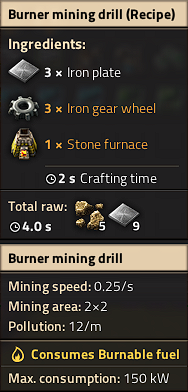

You'll need to craft some extra drills. If you hover over drill in the crafting menu, you'll see two lists of materials. The first list shows the components needed to make the drill; the second one at the very bottom of the tooltip window shows the raw resources needed to craft it. Unlike other games, you do not need to create the pre-requisite items before you select the item you want to make. All required items are crafted for you. You can see this process happening on the bottom left of the screen, where your Crafting Queue is. You can also queue up more crafting orders, as long as you have the necessary materials on you, and they'll get carried out one after the other.

Now that you can afford some extra drill and furnaces, you should automate the acquisition of both coal and stone. These are easy to set up and work essentially the same as the iron setup. For Coal, you can have two drills facing each other: they'll run on the coal they get fed by their partner and you can collect the surplus.

Don't forget that you can collect resources from machines without opening their inventories, with CTRL-LMB. You might also want to activate the detailed view, by pressing the ALT key once. You can deactivate it by pressing ALT again.

And for stone you can have the drill output directly into a chest.

Once this is all setup up, you will probably want to make it go faster. Set up more drills with furnaces for the iron, setup some for copper and maybe lay more drills on the coal to cover for the extra coal production. In the early game, the most used resource is iron, so you'll probably need twice as many miners on iron than copper, if not more. But expect copper to become more and more important the more you mess with electricity and electronics!

More automation

Great! So now you have four or so furnaces making iron, a couple making copper, some stone production and a good amount of coal production. But you know what really sucks? Having to run the coal around to all your other machines, right? Well let's automate that too! Conveyor belts and inserters are the way of the future! The output slots on the drill can also output onto conveyor belts to be transported to your other machines.

Now that we can take our coal to other places with no effort, we just need a way to input the coal into those machines.

This is where Inserters step in. In the first few stages of the game, you can use Burner Inserters as a cheap way to move items from anything to anything. You can move objects from the ground, chests, machines and put them wherever you want.

Burner Inserters themselves require coal to run though, which makes this a little counter intuitive to have to fuel them instead of the machines you are trying to fuel anyway.

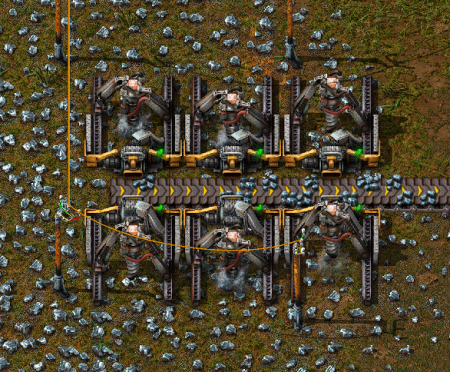

Here is a small example of inserters working. Notice that the flat line is where the inserters will pick up from, and the arrow is where they will place the item. To see this in your game you need to go into the game's menu, then press Options, Graphics and turn on the option "Show inserter arrows when detailed info is on."

Okay, so now we know how to automatically mine things and then how to automatically move things from one place to another, and then to place said items into machine or out of machines.

Next up we want to get some electricity so that we can have inserters that run off that instead of fuel.

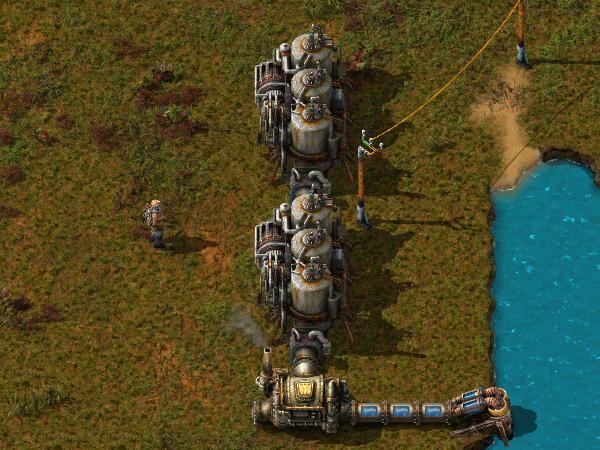

Electrical power

Electricity. This is where things start to get interesting. We're going to need a single Offshore Pump, a boiler and two Steam Engines. These are really simple to set up, they just require thirty-some iron plates per steam engine and 5 stone. The offshore pump goes in the water and needs no power to run. From there, you can either use pipes to transport the water to boilers, or you can run boilers straight from the pump. Water is fed into the boiler through the connection on the short side, as shown in the picture. If the boiler is fuelled, it will output steam in the middle of one of the long sides. The steam output of the boiler then connects to the middle of the short side of the steam engine. Make sure you connect it in the right place or it won't work. You can see where you can connect boilers and steam engines if you turn on the detailed view (press the Alt key). Boilers allow water to flow through, you can place multiple boilers next to each other and all will get water. Similarly, steam engines allow steam to run through, so you can have as many engine as you want connected in a row. Here is a small example.

Now you need to use power poles to carry power to your machines. Place some down so that their coverage area (the blue square) overlaps each steam engine in at least one square. If they are going to connect, the machines that use power will be shown with a blue outline around their edges.

If the steam engine is producing power but nothing is using it, it'll show a yellow flashing icon: right now it's showing because we don't have electric machines yet!

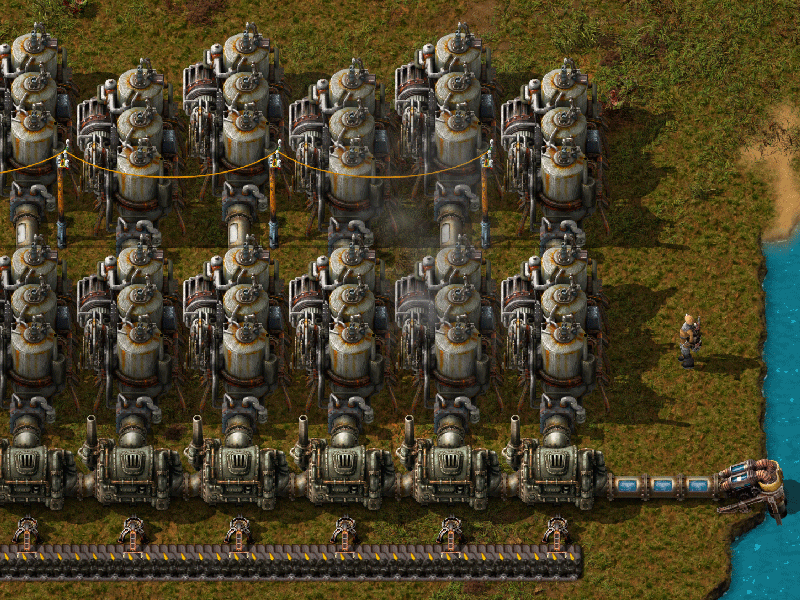

Your power setup can look however you want it to look. A boiler produces exactly as much steam as two steam engines can consume in the same time, so the usual method is to have a line of boilers each connected to two steam engines. The boilers are supplied with coal via inserters that take coal from a transport belt. A pump produces enough water for 20 boilers, so the most often used setup contains 1 offshore pump, 20 boilers and 40 steam engines. The example above is easily expanded into this efficient design. But hey, this game is all about experimentation and for you to be able to find ways to do your own things! So get to it, and show off your own unique designs!

Using this power is as simple as creating a machine that runs on electricity and placing a power pole close enough to it that the blue square touches the machine, just like you have to do at the power plant with the engines. Make sure that there is a line of power poles that actually connect to your power plant.

Now that power is explained, we need to increase our resource production.

However, if you want detailed info on your power production/consumption, you can check the Detailed Electric Network Info, opened by clicking on any powerpole.

Re-thinking our resources and research

Next we really want to get onto automation of items, not just the smelting of ores.

Before we can get to that though, we're going to have increase our production of ores. This is where things start becoming a little tricky and there are few things you want to do at once. We really want to be able to set the factory to make things and let it go. But for that we need some extra utilities which we don't have and need to get through research.

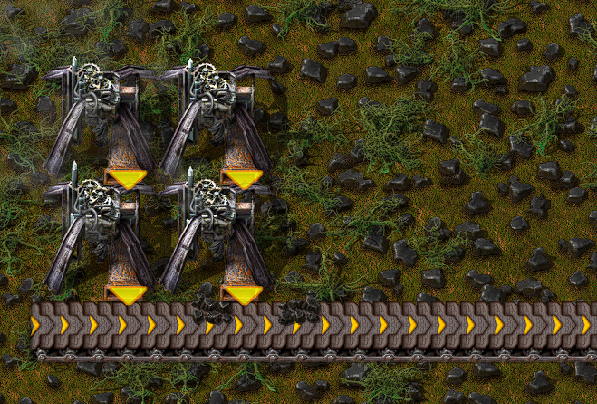

We haven't even touched on that yet! Let's start by cranking up our resource production. Now that we have electricity, we can use Electric Mining Drills. These are much better than those scummy Burner ones. They work exactly the same except they are twice as fast and they don't rely on fuel, as you could guess by the names. You can have them to output your raw resources onto belts and get them to a place where you can mass process the ores into plates. Here is a small example of what you could do, but let your imagination and your calculating logic figure out other, maybe even better ways of doing it! You want ore to be split more or less evenly on each side of the belts. This helps with the amount of resources that can be carried to your base of operations on a single belt.

This is once again easily expandable all over an iron deposit. This conveyor belt can then take all of the ore to some sort of processing area. The processing area needs some machines that we currently don't have due to limitations in our research.

Most importantly, we want the long handed inserter. This inserter is able to reach twice as far as a normal inserter! It is very useful for bringing or placing items to or from conveyor belts that are one extra tile away. So what we need to do is to make some science labs. They don't cost too many resources, but take a little while to make. Craft one or two of them and connect them to power. When you first place one, you are going to get a popup asking you want you want to research. We really want automation right now. This gives us our inserters and the Assembling machine 1, which is going to be very useful in the near future.

You'll notice that the cost for this is 10 Science Pack 1's, or "red potions" or "flasks" as some people like to call them. These are simply another crafted item, which you should craft 10 of now and place them in your labs to begin researching. While you are waiting for your flasks to craft or your research to complete, let's continue building an ore processing center. We want a line of copper, iron and coal to be available for this area. Despite being in the electric era, our furnaces still need coal until a little further down the line.

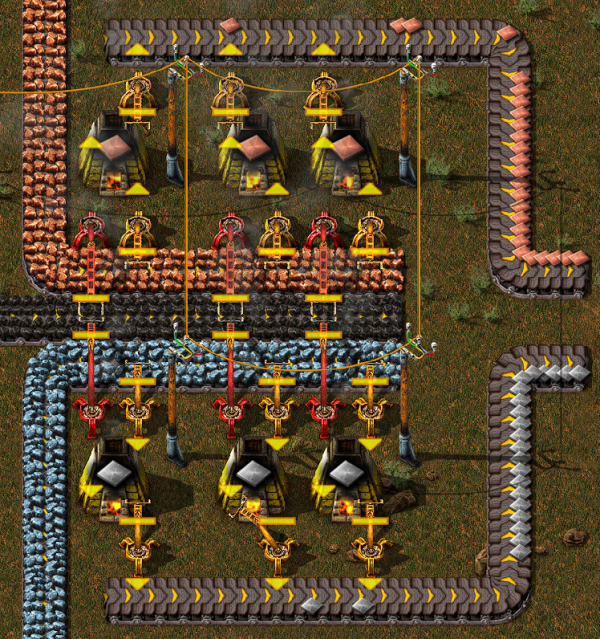

Below is another sample of how you could set up your area. There are efficient ways of making them that you might see on the forum, but if you want to learn about what they are and how they work, you can either experiment yourself or search the wiki/forum for some better designs.

As per usual, I leave this area with plenty of room to expand later on when demands become higher. The important parts about this is that you need the red, long handed inserters to be able to reach the coal in the middle to fuel your furnaces. You need seperate belts for your incoming raw materials to be able to be processed, and then another belt outside of them to handle the output after they have been smelted. These materials can then go straight into your base to be made into a myriad of other things. Finally, we have a steady and upgradeable supply of copper and iron plates, and we can get into further automation with the assembling machines so we can automate creation of things like Science Packs, Ammunition and every other item that the player themselves can craft, but without you involved at all!

Automating that research

Ok, so a fair amount has happened. Now, to be able to progress into later parts of the game with better research we are going to want automate the process of making science packs and putting them into the labs. This way we won't have to worry about research any longer.

There are many designs that you can find on the forums, but I'll show you something simple, letting you find what works for you. I would highly recommend that you research Logistics as your next research, and in fact manually craft the science required for this. The logistic research gives you some important things: the splitter, the underground belt and the fast inserter. The splitter and underground belts are some of the most important items you'll get at this stage. They do pretty much what their names imply.

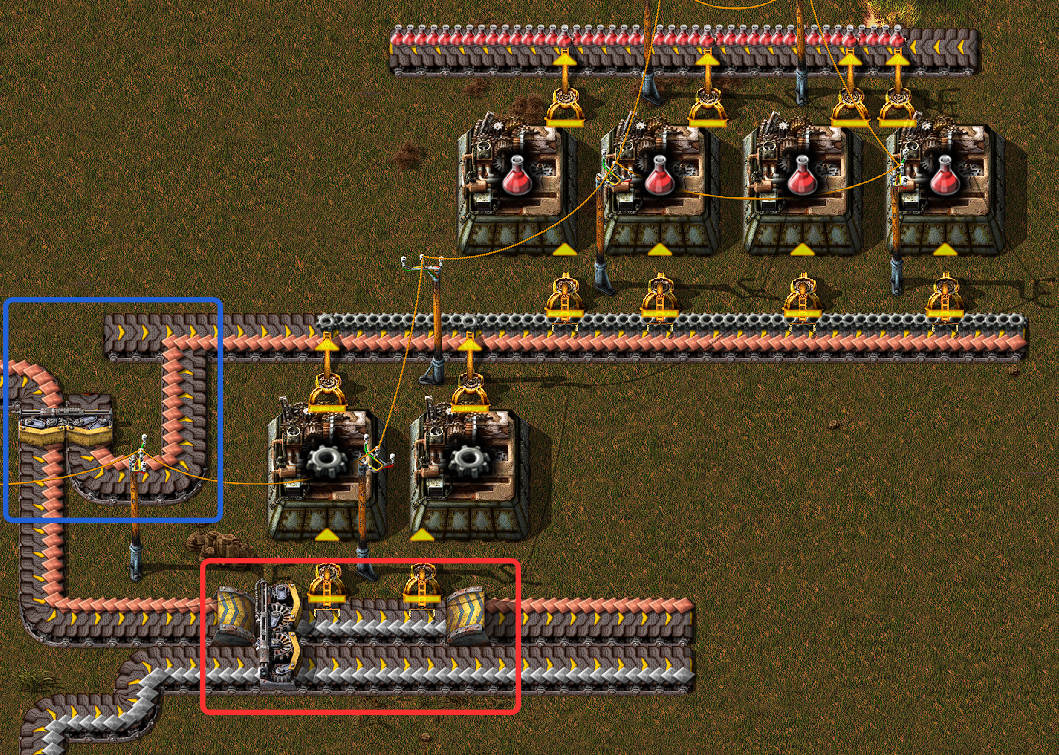

So what do science packs require? We need copper plates and iron gears. So far we have only dealt with raw resources, how do we make craftable things? The Assembler answers your prayers! If you place an assembler down and open its interface, it asks you what you would like it to craft. Once you select one, if you put the ingredients in that it requires it will craft the item and you can pull out the finished product. In the case of red science packs, we will need an assembler making iron gears, and an assembler making the actual packs. A nice way of doing this is to have a conveyor belt with 1 side containing the copper plates and the other side taking the gears from another assembler like below.

Now this picture uses a few neat little tricks that I will explain in detail. If you have your plate belts seperate, and you want them running side by side there can be issues with trying to grab one or the other resources from the far belt. Yes, you could use a long inserter, but in some cases you don't want this (e.g. you need a fast inserter to get resources quickly into your assemblers).

The area in red is a good way to get around this. By having a splitter, you can move the far belt from your production in close while also allowing it to continue down the line for later use. For the copper, we use an underground belt to go underneath the area that is now taken by the far line which also allows the copper to continue on. Once again, this is only one possible method of doing things and you are in no way obligated to follow it.

The area in blue is a quick way to allow copper to continue down the main line, while also splitting some off for our red science assemblers. Notice how when it joins the line that the gears are on, they only join the bottom side of the belt. The little extra belt that I added to the left stops the belt from becoming a turn, and therefore makes the items only join the side I want them to. The rest is simple: the gears and copper get pulled into the assemblers, they make the science and then it gets pulled out again on the other side. These flasks can then be transported to some labs to automatically do your research for you, for example like this: