Archive:Smart inserter: Difference between revisions

No edit summary |

No edit summary |

||

| Line 38: | Line 38: | ||

==== Condition part ==== | ==== Condition part ==== | ||

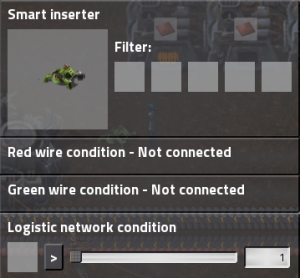

:[[File: | :[[File:smart_inserter.png|thumb|300px|Example condition: "Work only if the count of [[Iron plate]]s is lower than the amount of [[Steel plate]]s." Instead of the steel plate you can use a constant value.]] | ||

This switches the smart inserter on/off. It will work only if all set conditions are true; see below. | This switches the smart inserter on/off. It will work only if all set conditions are true; see below. | ||

Revision as of 22:15, 9 February 2016

More advanced electric inserter. In most cases, the smart inserter will be used to stop production of an item after a certain condition is met (e.g. enough items), when configured as output on an assembly.

Usage

Works at the same speed as a fast inserter. It needs to be configured to work. Configuration is done by opening the inserter interface (right mouse).

Wiring

When used for Circuit network this needs to be wired:

You can use the copy/paste (Shift-RMB for copy and Shift-LMB for paste) to copy the conditions and the connected wire.

The pole needs to be in wiring-reach and and you need to have wires in your inventory.

Configuration

The smart inserter interface has two parts: the "filter" and the "condition".

Filter part

If used (you are not forced to use the filter, it works also by using only the condition part!), the smart inserter moves only items which are in this filter. Up to five items can be filtered.

The inserter will then pick up only "filtered" items from a belt or other stacks (chests, assemblers, etc.). For example, if a belt contains iron and copper plates, and filter is set to iron plate, the inserter will take only iron plates, and won't touch copper plates.

Condition part

Example condition: "Work only if the count of Iron plates is lower than the amount of Steel plates." Instead of the steel plate you can use a constant value.

This switches the smart inserter on/off. It will work only if all set conditions are true; see below.

Condition could be based on

- red/green circuit (the first two lines, but you need to connect red/green wire to the inserter first!)

and/or

- logistic network (the last line, but you need a Roboport and the inserter must be inside of the logistic area).

The condition part needs three parameters, which can be changed by just clicking in the interface:

- item-type (or bus-signal-type)

- operator (greater than, lower than and equal are possible)

- value (you can use the slider or type in any positive number)

Typical use: Limit input/output of assembly machine

If the circuit and/or logistic network contains < X items of this type then load (more common: unload) an assembly machine.

As soon as X items are in the network, the assembly machine is not loaded/unloaded any more.

Untested: Usually it's easier to limit output/unload (and not the loading), so items are not removed from assembly machine and when internal storage of the assembler is full it will stop producing. This is in most cases a bit better, because it doesn't clog.

There are some examples in the forum, which will show you some of the common and not so common usages.

See also

Please refer to the Circuit network to see more.

Using both

Finally you can use both, filter and condition, so it will only move items of one type if there are less/more than X items of that type in the logistic network (or wires).

Not working by default

This device works only if

- it has a filter set and/or

- it is connected to a Circuit network and/or Logistic network.

When connected to a network, it begins to work immediately, because the "no condition" is a valid condition.

More than one condition

Set one or more conditions, and the inserter will follow the instructions by combining it with logical 'AND'.